The project REMHub, funded under the Horizon EU call HORIZON-CL4-2024-RESILIENCE-01-08, aims to create a cutting-edge innovation hub propelling EU excellence in the supply of Rare Earth Elements (REEs) and the manufacture of permanent magnets. The extraction of valuable elements from industrial side streams is a key activity, along with the prospection for primary sources.

Within this context, Opigeo and the Politecnico di Milano, along with partners from the Universities of Basilicata, Bari, and Sassari, and with the support of the Italian Ministry of University and Research through the project CAMEBAX, are optimizing processes to extract Scandium and Rare Earths from red muds stored in ponds at the Eurallumina site in Porto Vesme, Sardinia, Italy.

The team working on this topic will present the first results of the process development research at the 8th Multidisciplinary Symposium on Circular Economy and Urban Mining (SUM 2025), which will be held in Procida, Naples, Italy, on May 21st–23rd, 2025.

The red muds in Porto Vesme are stored in ponds covering an area of 159 hectares and amounting to about 30 million tons. Even though the rare earths content is nearly one order of magnitude lower than in primary sources, the concentrations of Sc, La, and Y are in the range of 100 ppm, and those of V and Ce are in the range of several hundred ppm.

Extraction and recovery of these elements is therefore feasible and economically interesting. The recovery of Sc alone could be worth about €3 billion, while the recovery of all valuable elements is estimated to be worth €7 to €9 billion.

The process is divided into three parts. The first is the leaching of the red muds to solubilize the elements of interest. The second is the enrichment of the leachate solution, and the third is the selective recovery of the valuable elements. What remains can be further processed to recover major elements such as Fe, Al, and Si, thereby fully exploiting the chemical energy content of the waste material.

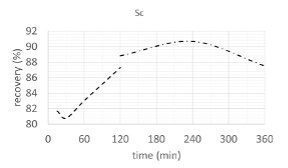

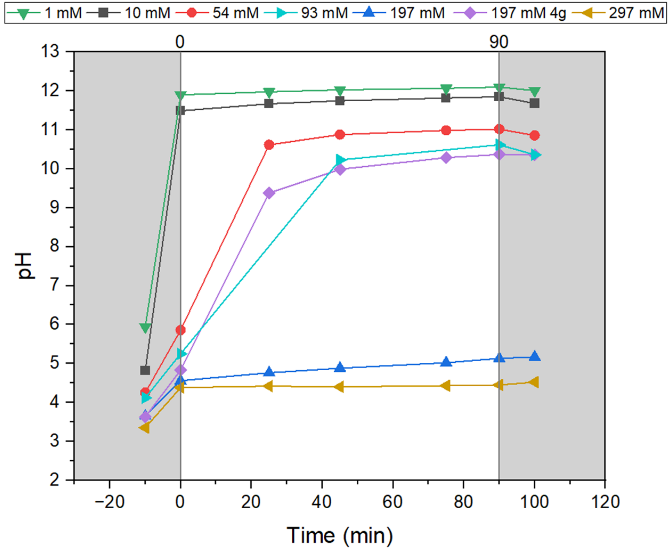

The leaching step involves acid dissolution, which is being optimized to use diluted mineral acid and high pulp concentrations in order to limit resource use and environmental impact. Under these conditions, the recovery of Sc, for example, reaches approximately 90%.

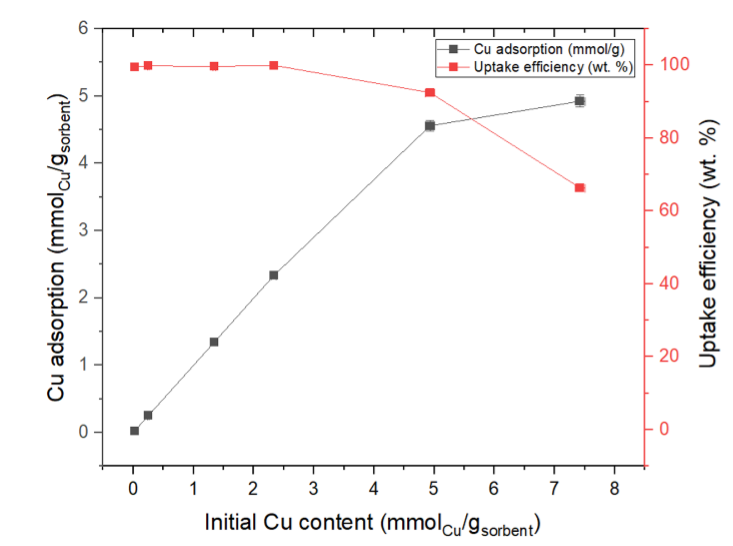

The enrichment of the leachate is proposed through multiple solid/liquid adsorption cycles, without using potentially dangerous organic molecules. The solid substrate used in the adsorption process is itself a product of circular economy principles: it is based on ladle steel slags, a side stream that is routinely landfilled. The capability of these solids to capture metals has been proven and is now being tested for Sc and REEs. For instance, the capture efficiency of Cu is shown below.

Capture efficiency of Cu onto the solid substrate.

Finally, the selective recovery of the target elements will be performed using chelating polymers and/or separation membranes, which are being developed by other REMHub partners in Slovenia and Finland.

Using red muds as a polymetallic source—a kind of artificial mineral—while also recovering major elements such as Fe, Al, and Si, will complete the remediation of the site. This approach is aligned with initiatives such as SisAl Pilot and AlSiCal, which aim to produce aluminum and silicon from secondary sources via low environmental impact processes.

The process is now being implemented in the laboratory, with each unit operation tested individually. This work will be completed within the REMHub time frame, contributing to the establishment of the Hub. The Hub will offer services and demonstration units to European industry to strengthen resilience in critical raw materials supply, optimize resource use, and eliminate the environmental hazards caused by dumping and landfilling industrial side streams.