Extrusion-based 3D printing is no longer just a rapid prototyping tool. Today, it is evolving into a viable method for producing end-use industrial parts—driven by community innovation, improved hardware/software ecosystems, and advanced materials. This progress is opening new doors for circular manufacturing—particularly in Europe’s efforts to secure access to critical raw materials.

One promising example is the EU-funded REMHub project, which brings together 24 partners across five countries to strengthen the resilience of the EU’s value chain for Rare Earth Elements (REEs). A key focus is enhancing REE circularity through recycling, reuse, refurbishment, and repurposing—especially from end-of-life (EoL) electric machines.

In this context, extrusion-based 3D printing has emerged as a strategic enabler for revalorizing Neodymium-based magnets. AIMEN Technology Centre in Galicia, Spain, is collaborating with Haiki Cobalt (IT), Magneti Ljubljana (SI), and Politecnico di Milano (IT) to develop a method for producing high-performance 3D-printed magnets using materials recovered from EoL electric motors.

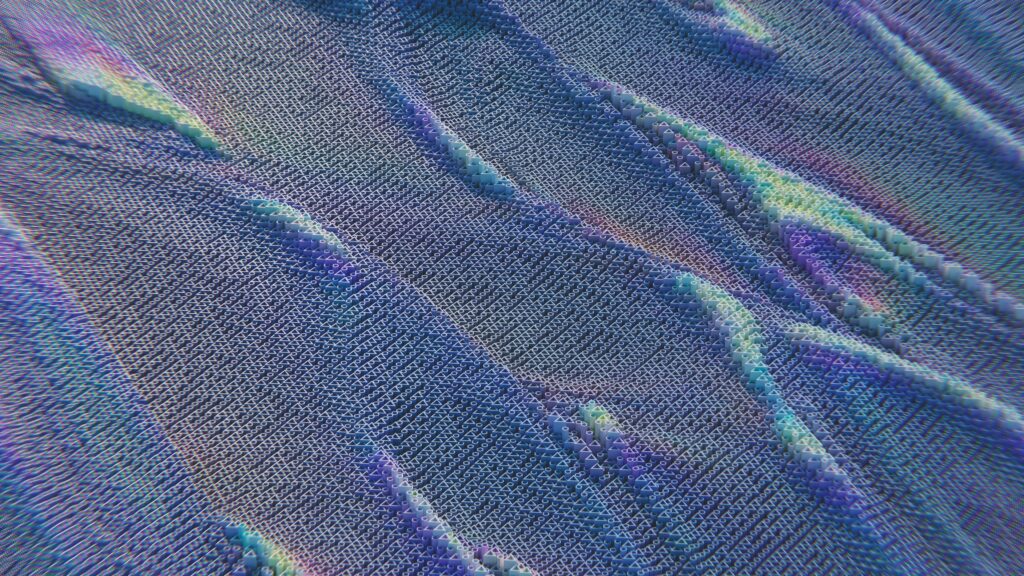

The approach centers on highly filled composites—materials containing over 90% by weight of magnetic particles. To process these challenging feedstocks, AIMEN is exploring both Fused Filament Fabrication (FFF) and Fused Granulate Fabrication (FGF). While FFF is well-known in research and maker communities, FGF—using pellets instead of filaments—offers industrial scalability, reduced material waste, and compatibility with recycled thermoplastics.

These processes allow NdFeB magnets to be processed into fine powders, compounded with just enough thermoplastic binder for mechanical integrity. When heated and extruded, the material becomes a 3D-printable feedstock that combines magnetic functionality with design flexibility. Unlike traditional manufacturing, this enables the creation of complex, custom-designed magnetic components.

What’s more, applying external magnetic fields during printing allows for controlled orientation of magnetic particles, enabling tailored, anisotropic magnetic properties—a major benefit for specialized industrial use.